One of the main challenges to omnichannel logistics is the costs involved if the delivery service is not optimised. BORIS (buy online, return in store) incurs one of the highest margin losses in comparison to traditional in-store purchases due to the extra costs of fulfilment.

In addition to the cost of implementing these different services across channels, a further challenge is inventory visibility and metrics. Without a connected inventory management system, retailers run the risk of not knowing where, how many and which items are in stock. It can lead to losing customers if they are unable to purchase exactly what they want, when they want.

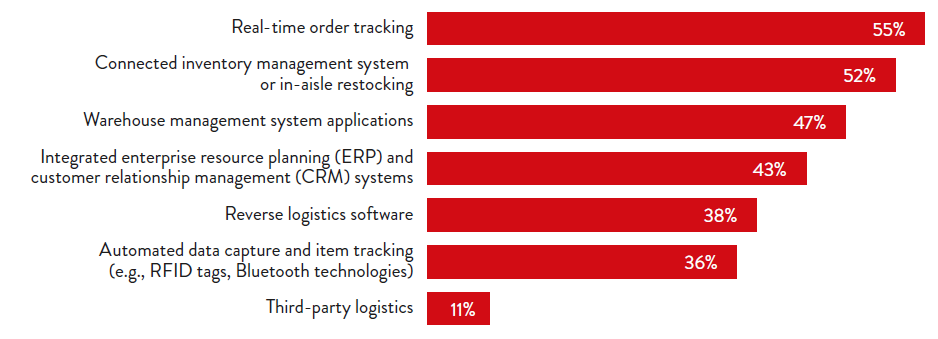

There are a whole range of solutions that can be applied across logistics operations so that logisticians and retailers can have a real-time overview of their stock, including items that are in transit. They keep their customers better informed, but only a minority of those who are undertaking omnichannel logistics are using these to improve their operations.

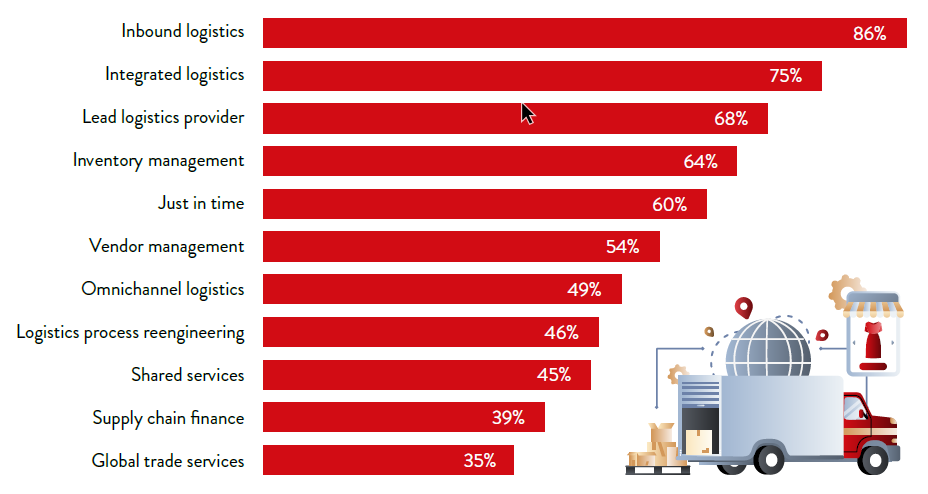

With just 11% of respondents using third-party logistics to improve their omnichannel model, it bares the question as to why. Third-party logistics providers are potentially the most untapped solution that is available since 49% of these partners are already offering omnichannel logistics. Retailers are not only able to benefit from a logistician’s digital tools, experience and strategic consultation but can also avail of the other services these providers already offer such as inventory management and global trade services.

Inventory management and global trade services are particularly important for those retailers who require support in reverse logistics and clearing customs with cross-border trade. Digital tools are often a key requirement to undertaking these activities successfully. For example, integrating advanced inventory management technology (barcode scanning, RFID, cloud computing, etc.) can offer real-time insights into inventory while automation as conveyor systems, robotic pickers and AGVs (automated guided vehicles) can aid seamless movement of goods within warehouses. Some results show an increase of picking accuracy from 95% human accuracy to 99.9%. Robotic accuracy and costs for shipping and holding in its turn can be reduced by up to 30% and 50% respectively